Natural Gas Fire Quench Furnace Radiation Continuous Natural Gas Fire Quench Furnace

Industrial Furnace

Introduction

This article takes an in depth look at industrial furnaces.

You will learn more about topics such as:

- What is an industrial furnace?

- How a furnace works

- Types of industrial furnaces

- Methods for heating furnaces

- And much more…

Chapter One – What is an Industrial Furnace?

A furnace is a direct fired device used to provide heat for industrial processes that require heat in excess of 400° C (752° F). Any industrial application that relies on heat to create a reaction or heat materials for production uses an industrial furnace. Of the many types of equipment and machines used for production and processing, furnaces are the most reliable. Through the combustion of fuels and gases, raw materials and products are heated by direct or indirect contact.

The construction of a furnace includes heat exchangers, air and flue blowers, fuel control, burners, pilot or ignition device, control circuitry, and a thermostat. Though these are typical components, furnace designs vary to meet the need of an application or function. Furnaces differ mainly by the types of fuel and how combustion is initiated. Regardless of the differences of operation, all furnaces serve the primary purpose of providing heat.

Chapter Two – How Industrial Furnaces Work

Different furnaces function differently and burn different types of fuel. For many years, furnaces were powered by wood or coal; this required constant refueling for continuous heat. Modern furnaces have moved on to fuels that are supplied automatically.

How a Furnace Works

How a Furnace is Fueled

The critical element in the operation of an efficient and economical furnace is its fuel. Though coal and wood were used for many years, they polluted the environment, required constant feeding, and made it difficult to keep a steady temperature. Modern furnaces have fuel fed directly into the furnace at a controlled rate or operate using electricity to maintain even temperature.

Fuel fired furnaces are the most widely used. The nature of the fuel determines the design of the furnace but is not relevant to modern furnaces. As with any type of heat operated device, the supply of oxygen is important to the furnace's efficient operation.

Electric furnaces use induction or resistance heating. The efficiency of electric furnaces, and the fact that they do not release flue gases makes them environmentally ideal. Unfortunately, the operation of an electric furnace is expensive.

Resistance heating is the most expensive type of electric furnace, and it uses a circulating fan to maintain temperature uniformity. Resistors are made of various types of materials or the load to be heated may serve as a resistor.

With induction heating, electricity passes through a coil that surrounds the load. The frequency of the current is determined by the type of load. The coils are water cooled to prevent them from overheating. Induction heating is used for heating a localized area of a workpiece.

Furnace Burner Types

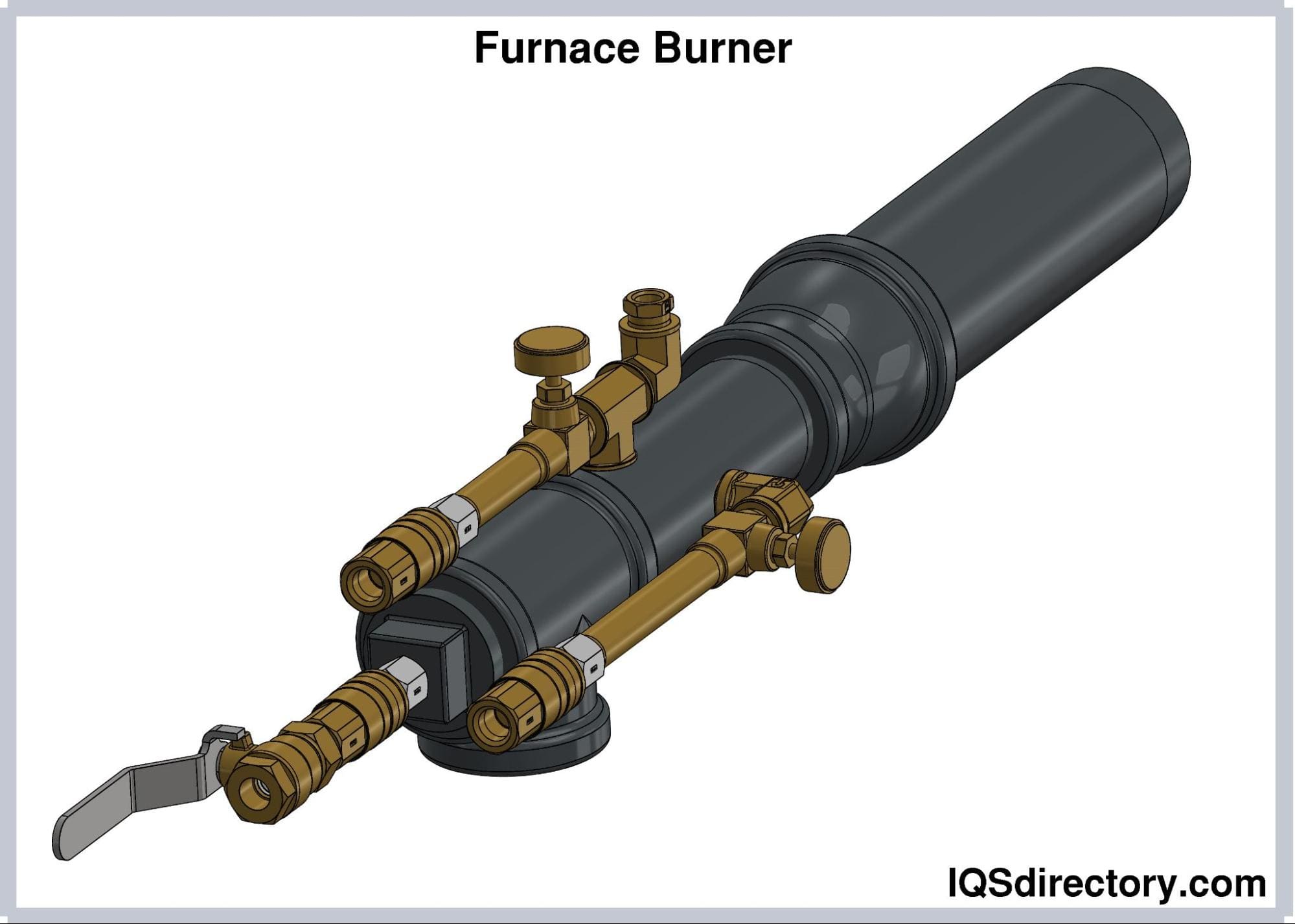

The fuel is supplied to the burners where, predictably, it is burnt. Most furnaces have more than one burner that can be mounted in different sections of the furnace depending on its design. The burner has an oxidizer to change the chemical energy into thermal energy. The type of fuel used in a furnace is determined by the burners. They mix the fuel and air and ignite them. Burners must be stable, cost effective, reliable, and energy efficient, and they must have proper flame dimensions.

The components of the burner include the nozzle, mixing tube, downstream connection, and air fuel ratio control. The fuel and air are mixed to produce the best quality flame; forced air is required for the mixing process.

Burners produce six types of flames: A, C, E, H, F, and G.

Type A

Type A is a conventional flame that burns forward and is shaped like a feather. It is used in all-purpose furnaces.

Type C

Type C is ball shaped with swirl and has a hot reverse flow. It is used in cubicle-shaped furnaces.

Type E

Type E has a very high swirl with some recirculation. Convex types are used to avoid flame impingement while concave types focus on hot spots. Both types increase direct radiation.

Type F

Type F has no swirl or recirculation and is long and luminous. Due to its luminous radiation, it is used in long furnaces.

Type G

Type G is also long and luminous without swirl. It supplies uniform coverage for long furnaces.

Type H

Type H has high velocity and low swirl with high circulation. It is fast mixing and used to force flow around the backs of furnaces.

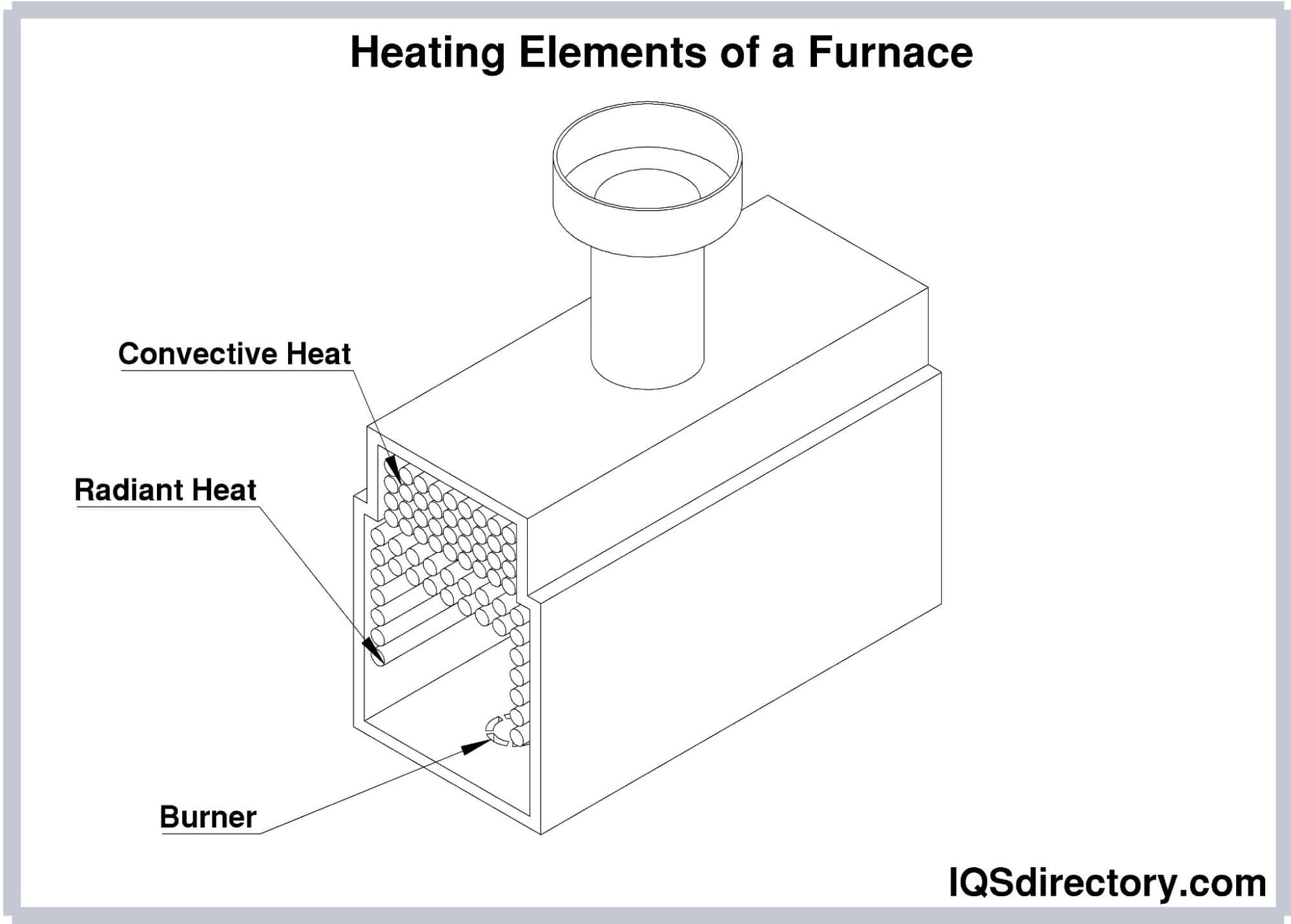

Heat Transfer in Furnaces

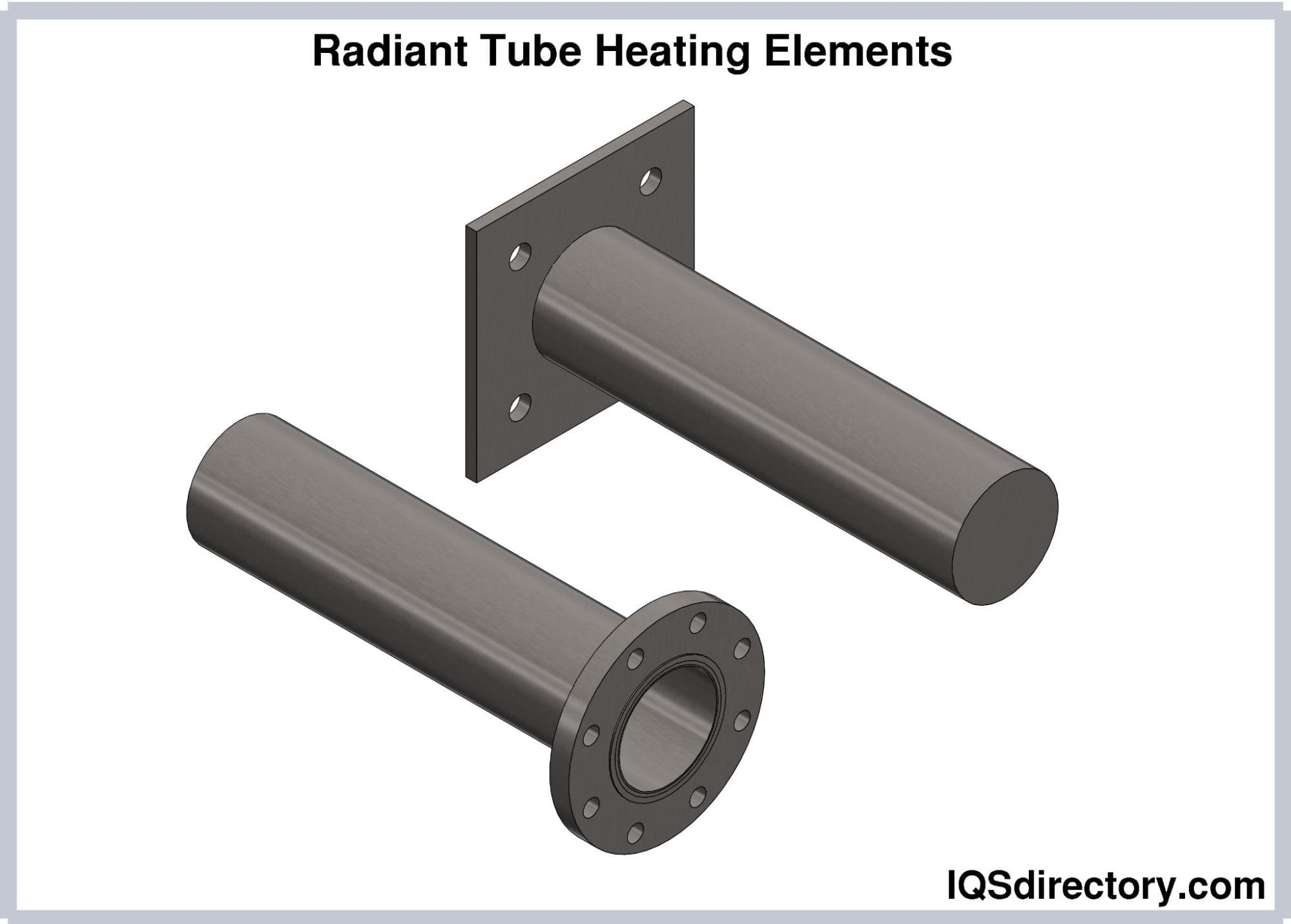

Heat transfer in a furnace takes place in three ways: radiation, convection, and conduction. The burners are located in a chamber that has tubes on four sides. When the burners are ignited, they transfer heat to the surrounding tubes by radiation. The process heats the fluid that is in the tubes that are close to the source of heat for radiation to occur.

Convection requires the flow of a gas or liquid to carry heat. In a furnace, there are tubes located above the furnace that catch heat as it leaves the heating chamber before it exits through the stack. This process helps maintain the efficiency of the furnace by preventing the waste of heat.

The conduction of heat happens in the furnace where heat is transferred to the tubes. Conduction is the transferring of heat through a solid surface. In the case of a furnace, the tubes are the surface heat is transferred through.

The diagram below depicts radiation and convection.

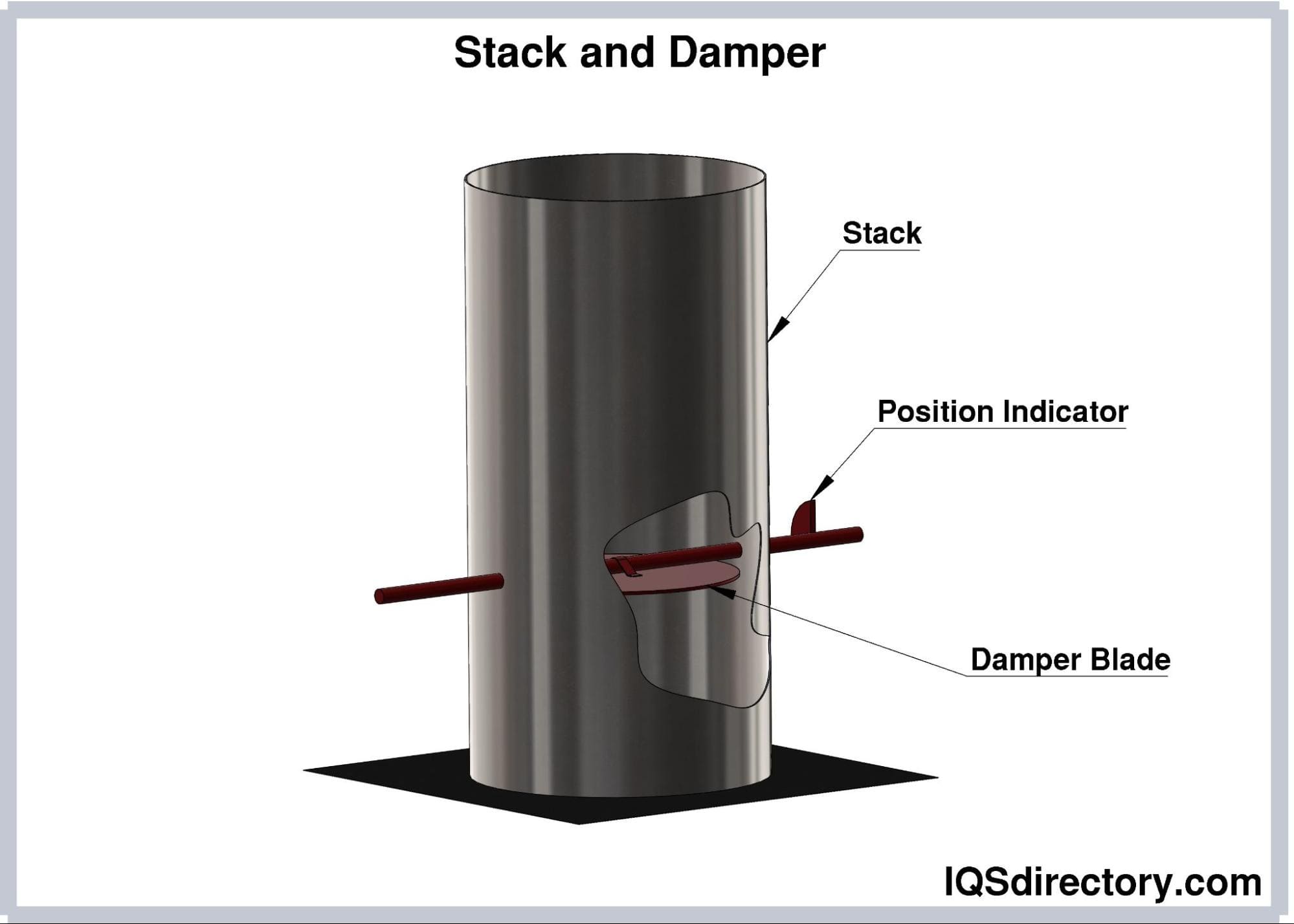

How Furnace Stacks Work

The stack is a chimney or vertical pipe that disperses the hot air or flue gases from the furnace heating process. The emissions from the stack are strictly controlled and monitored to avoid the release of harmful gases into the atmosphere. Flue gases contain a variety of materials, including carbon dioxide (CO2), water vapors, nitrogen, and oxygen. With the rise of environmental concerns, most stacks have contaminating materials filtered through air scrubbing or some other method before release. The high pressure outside the stack is the force that drives the flue gases out.

Inside some stack configurations are damper blades, which are thin metal plates that regulate the flow of air. In large furnaces, dampers have multiple blades designed to protect the stack and prevent materials from entering the furnace. They come in sizes made to fit the diameter of the stack.

Chapter Three – Types of Industrial Furnaces

Furnaces serve the dual purposes of providing heat and assisting in production. Industrial uses of furnaces tend to center around the annealing, melting, tempering, and carburizing of metals. Though these are critical functions of furnaces, they serve far more purposes and come in designs to fit those differing functions.

Residential furnaces are simple devices designed to provide a sufficient amount of heat. Those designed for industrial use are more complex and provide far greater amounts of heat. The basic designs of the two types are similar but industrial use furnaces are more complex.

The selection of a residential furnace is rather easy since its purpose is to provide heat. In the case of industrial furnaces, there are a variety of parameters to consider, beginning with the purpose of the furnace and its importance in production. Industrial furnaces can be divided between direct contact and indirect contact furnaces.

Furnace Types

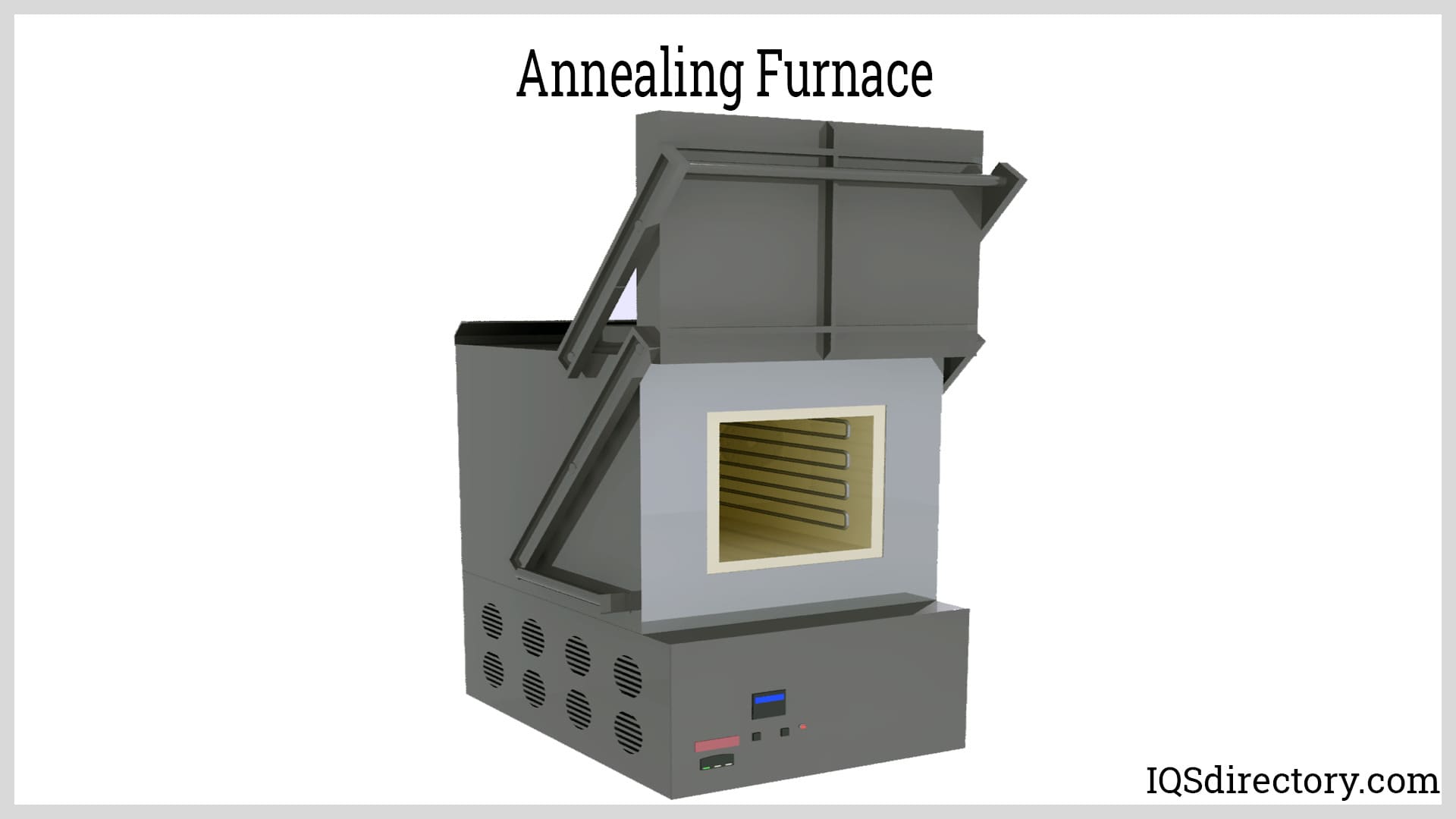

Annealing Furnace

Annealing is a heat treatment that softens metals to allow for their cold working to improve their mechanical, electrical, and other physical properties. Annealing furnaces relieve the internal stress of materials by heating them to their recrystallization temperature to make them ductile for further machining. After a workpiece undergoes annealing, it is rolled, drawn, forged, extruded, headed, or welded—these are processes that cause internal stress.

Ashing Furnace

Ashing is a process of quantifying the change in the weight of a sample as various components of the sample are burned away. It is a process of expelling organic material before it is analyzed. The method of ashing involves the complete combustion of the material being tested. Due to the complexity of the ashing process, ashing furnaces are designed specifically for the product(s) to be tested.

The typical ashing furnace has a heating element in an enclosure with a scale attached to weigh the sample before, during, and after it is burnt. An ashing furnace is relatively small with a chamber, heating element, heath plate, and chamber threshold, all of which can be easily replaced.

Ashing furnaces are used in the food industry to estimate the mineral content of food. Samples are heated to 600° C (1112° F). The dry weight of the ash provides data on the mineral concentration of the sample. The petroleum industry uses ashing furnaces to test the combustibility of their products and crude.

Bell Furnace

Bell furnaces are batch heat treatment furnaces that are capable of sintering or drying processes. The load is heated inside an enclosed dome. Bell furnaces are necessary when the workload is very high. They are not used for small batches and are powered by electricity, gas, or a thermal circulation system.

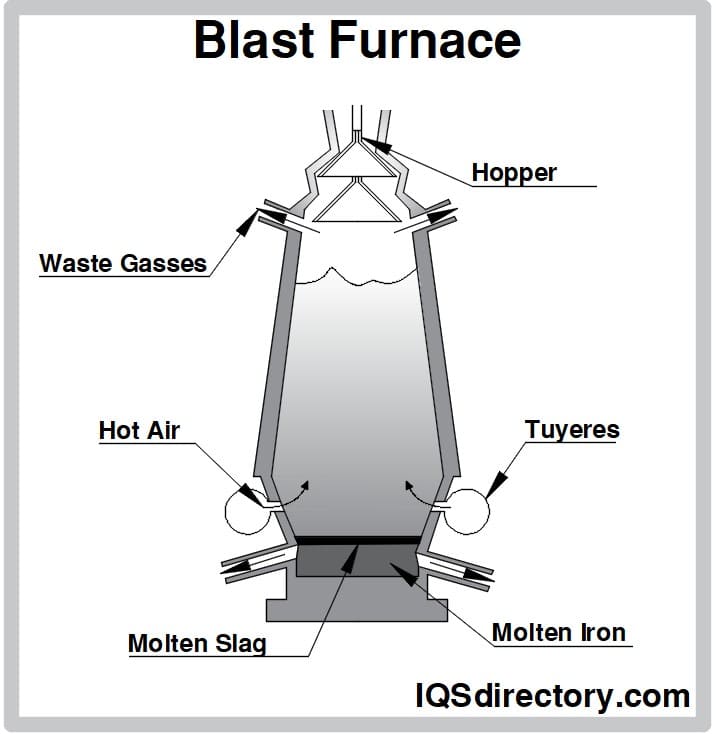

Blast Furnace

A blast furnace is a cylindrical furnace that is used for smelting, which is the process of extracting metals from their ores. The furnace is loaded from the top with ore, fuel, and limestone. As the components move down the cylinder, a reaction takes place between them that produces molten metal and slag. At the bottom of the furnace are parallel pipes that push hot blast air up the cylinder to create the reaction between the materials.

The parts of a blast furnace are the hopper, adjustable gates, rotating chute that blends the materials, fire brick, combustion chamber, gas burner, carbon brick, tap hole, and tuyere to supply air. The raw materials are loaded in the stack zone and progress to the barrel zone or reduction zone where the chemical reaction takes place.

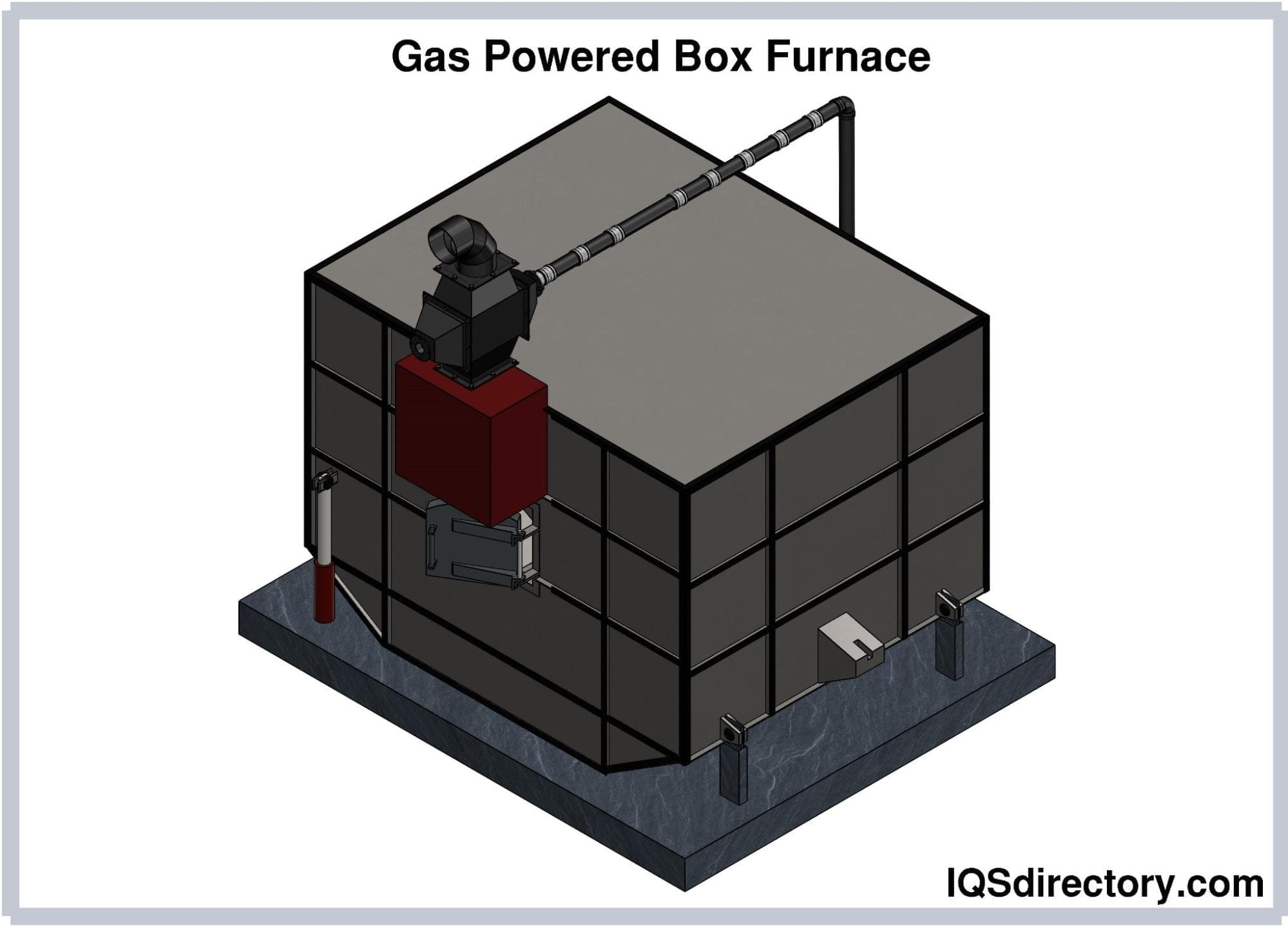

Box Furnace

Box furnaces are used for heat treatment, calcining, curing, annealing, stress relieving, preheating, and tempering. They have a very simple design, which makes them very versatile and problem free. Box furnaces can be designed with single or multiple zone heating with temperatures ranging between 1000° C and 1700° C (1800° F and 3100° F). They come in multiple configurations and sizes, from table top models to large heavy duty multi-level models.

Calcination Furnace

Calcination is a heat treatment wherein samples are heated to a point just below their melting temperature to produce thermal decomposition or to remove volatile substances. When ores are mined as carbonates or sulfates, the only way to extract the metal from the ore is to apply reduction; this is done in a calcination furnace.

In the process of calcination, the ore is heated to a high temperature in the absence of air or oxygen; this removes moisture from the ore. In some instances, calcination is referred to as purification since volatile and oxidizing portions are removed from the ore.

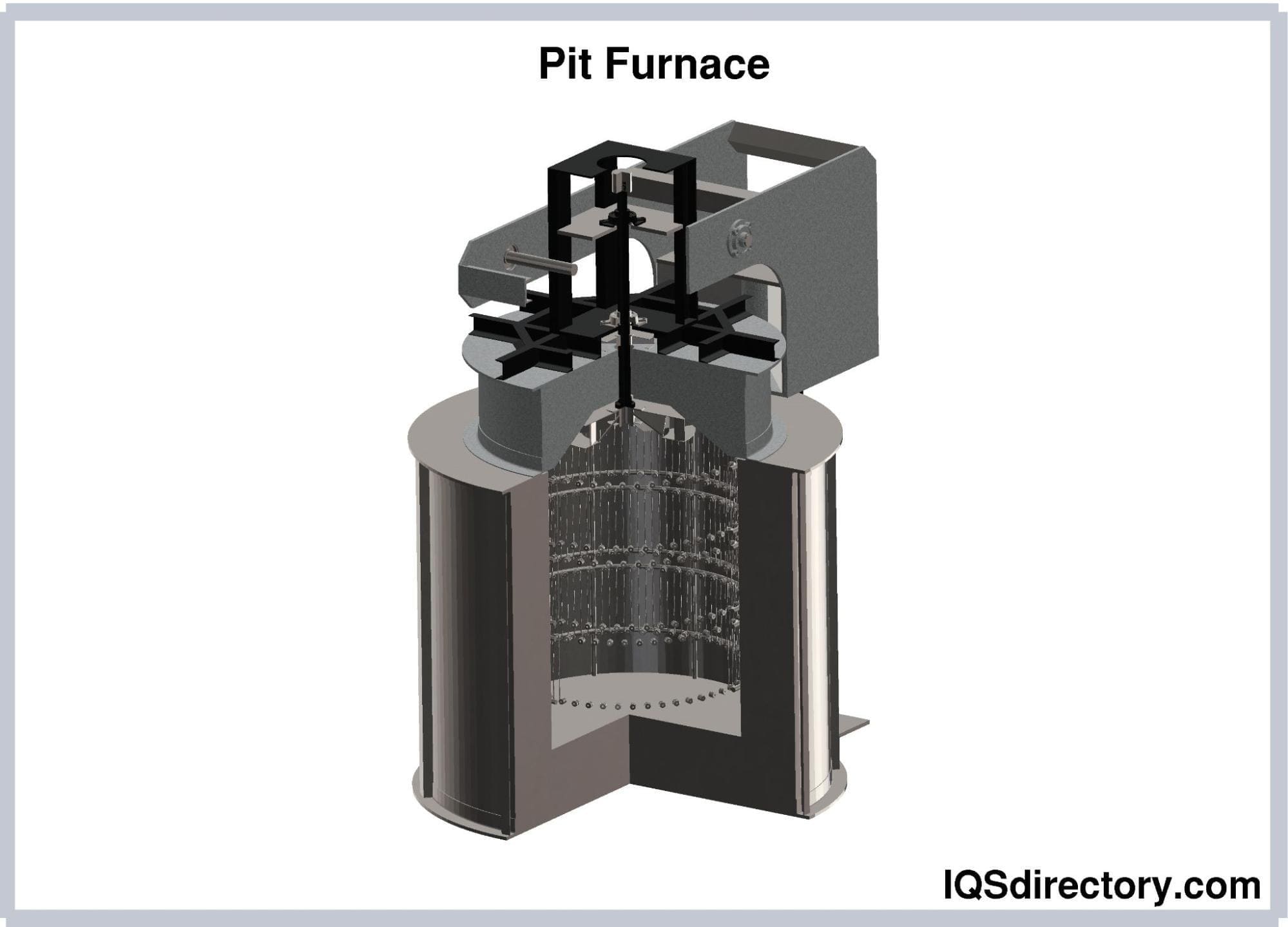

Pit Furnace

Pit furnaces are located at floor level and are top loading. Workpieces to be treated are held in fixtures or baskets or can be placed at the base of the furnace. Pit furnaces are best suited for heating long shafts, tubes, and rods. The main purpose of a pit furnace is to melt small amounts of metals for casting. Pit furnaces are fueled by coke.

Process Furnaces

Process furnaces are an essential part of several industrial operations as a method for preparing fluids. The two main types of process furnaces are electric and fired. Of the two types, electric process furnaces are the more expensive to operate but have the advantage of not producing pollutants.

Process Electric Furnaces

Electric process furnaces are used to heat a gas stream. Attached to the inner walls of the furnace's insulation are electric elements, which surround a process coil and radiantly pass heat though the coil to the fluid. All parts of the surface of the furnace are heated evenly but heating time zones can be included when specific temperatures are necessary. Process electric furnaces are used in the refining, petrochemical, and chemical industries.

Fired Process Furnaces

Fired process furnaces have the same function as electric process heaters, which is to heat a fluid to a desired working temperature. The fluid to be heated flows through tubes that are heated by a combusting fuel. Fired process furnaces are widely used by refineries, petrochemical plants, the chemical industry, gas processing, ammonia plants, olefin plants, and the fertilizer industry.

Several names are given to fired process furnaces including feed preheaters, cracking furnaces, fractionator heaters, steam reforming heaters, and crude heaters to name a few. Fired process furnaces reach temperatures of 3500o F or 1926o C. The created heat is released into an open space where it is transferred to tubes containing the fluid. The tubes are placed along the walls and roof of the open space. The heat is transferred by direct radiation convection or from refractory wall linings in the open chamber.

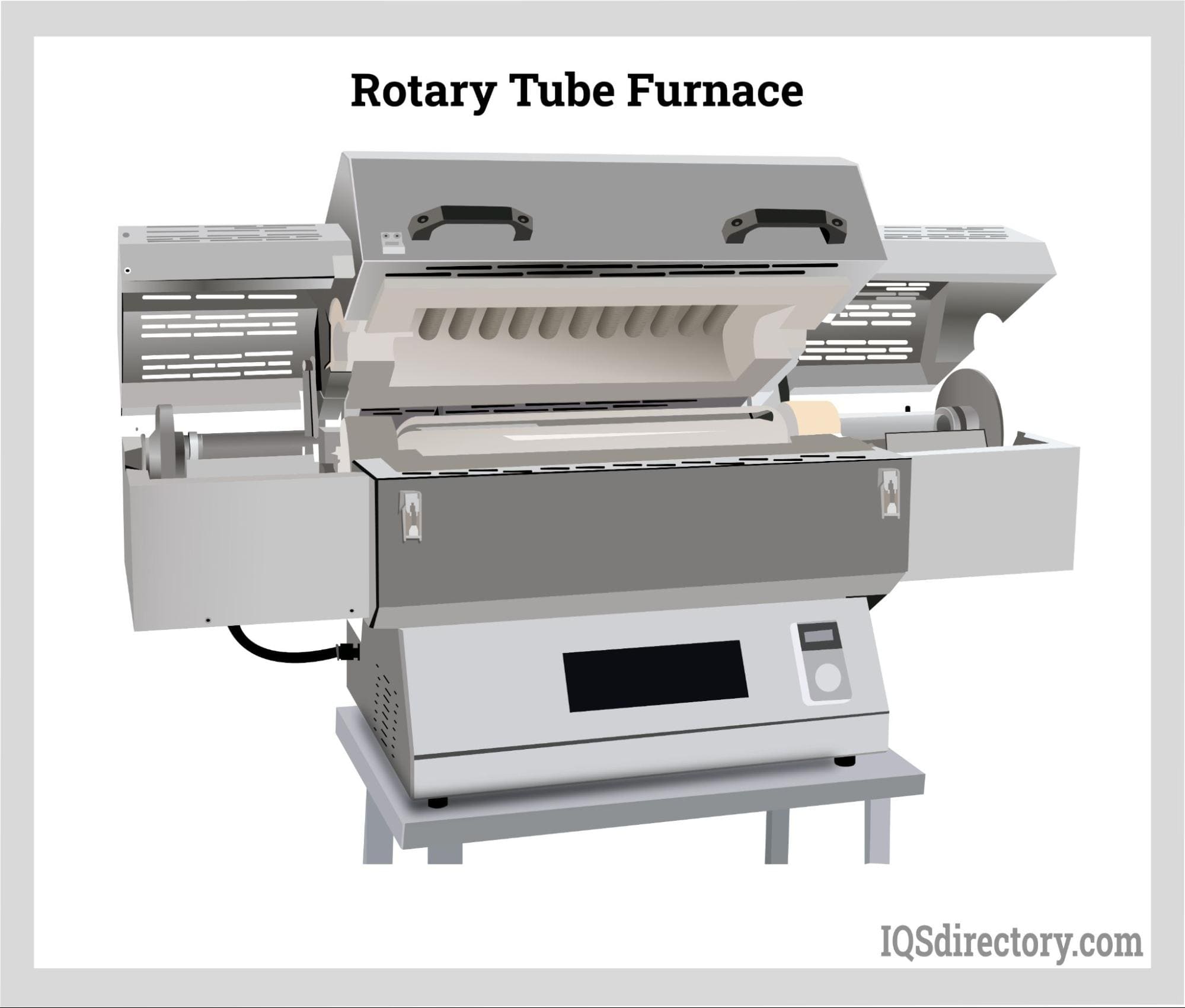

Rotary Tube Furnace

A rotary tube furnace is a heat treatment circular furnace that rotates during heat treating. Materials to be treated travel a circular path through the furnace as they are treated. Rotary tube furnaces provide a continuous processing method that applies heat in thermal zones where the heat source supplies heat to a rotating tube.

Quenching Furnace

Quenching is a process of rapidly cooling a workpiece from a high temperature, and it is used to form martensite in steel. The cooling material can be water or oil. Quenching furnaces are normally paired with a batch furnace, roller hearths, or pusher furnaces. Different quenching furnaces are designed to meet the specific needs of a given application. A necessity for quenching furnaces is precision control of the temperature to avoid uneven heating and overheating.

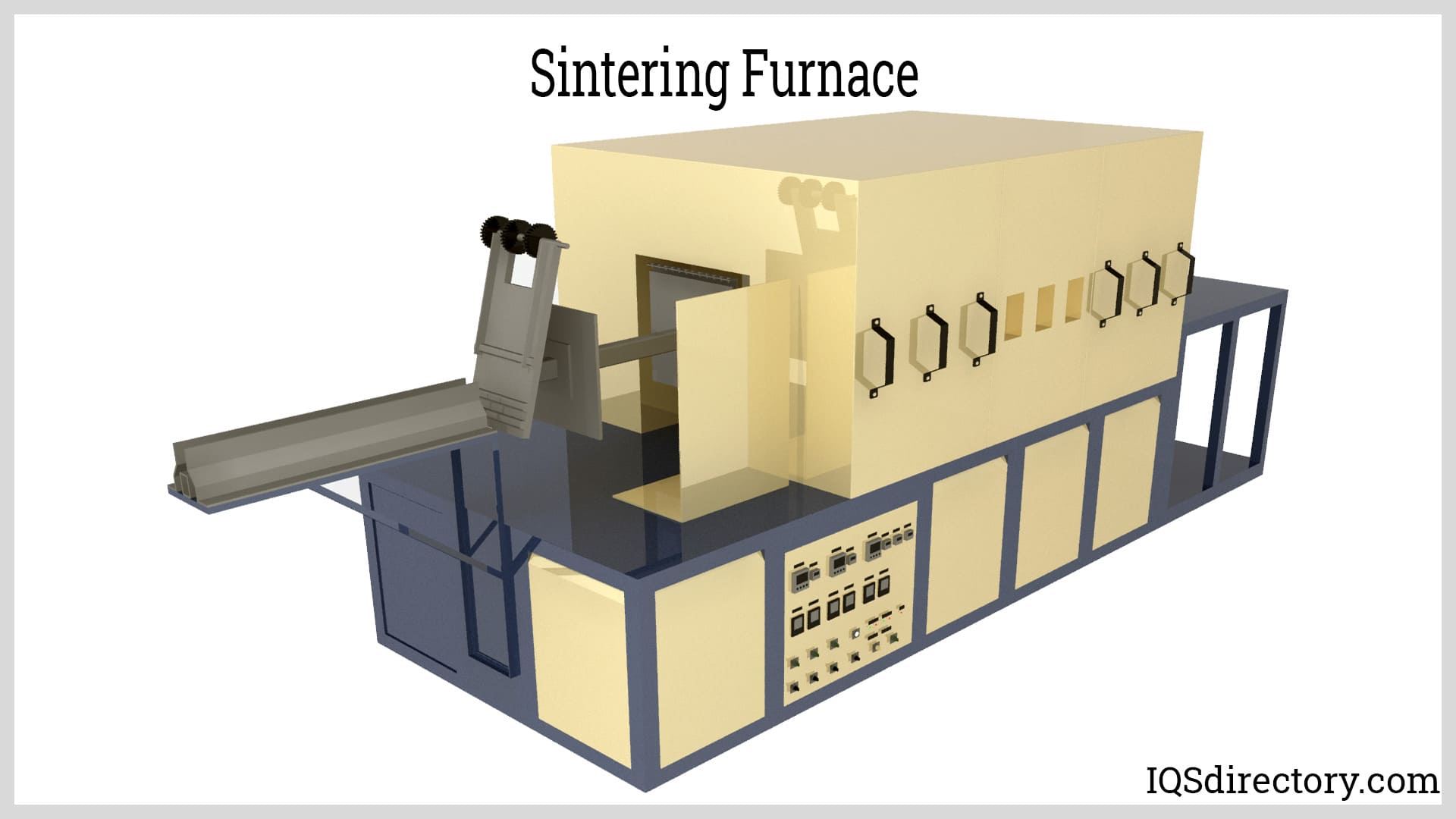

Sintering Furnace

Sintering is a heat treatment process designed to transform loose fragmented material into a solid mass. The amount of heat provided during sintering varies in accordance with the type of material but is always slightly below the material's melting point. During sintering, the porous spaces in a workpiece are minimized as the material is squeezed and shaped at high temperatures and pressures. The purpose is to heighten the material's properties, such as thermal and electrical conductivity, strength, and translucency.

Tempering Furnace

A tempering furnace is designed to heat treat metal products to increase their durability and hardness. Increasing the toughness of a metal product enhances the product's ability to withstand deformation and energy absorption before it cracks. Heat of a tempering furnace brings out the beneficial properties of a metal and improves its mechanical characteristics.

Tempering furnaces have ceramic heating elements that are lined with electrical coils to provide uniform heating of the chamber. There are different heating ranges depending on the material to be processed. Tempering takes place at temperatures between 300° C and 750° C (542° F and 1382° F).

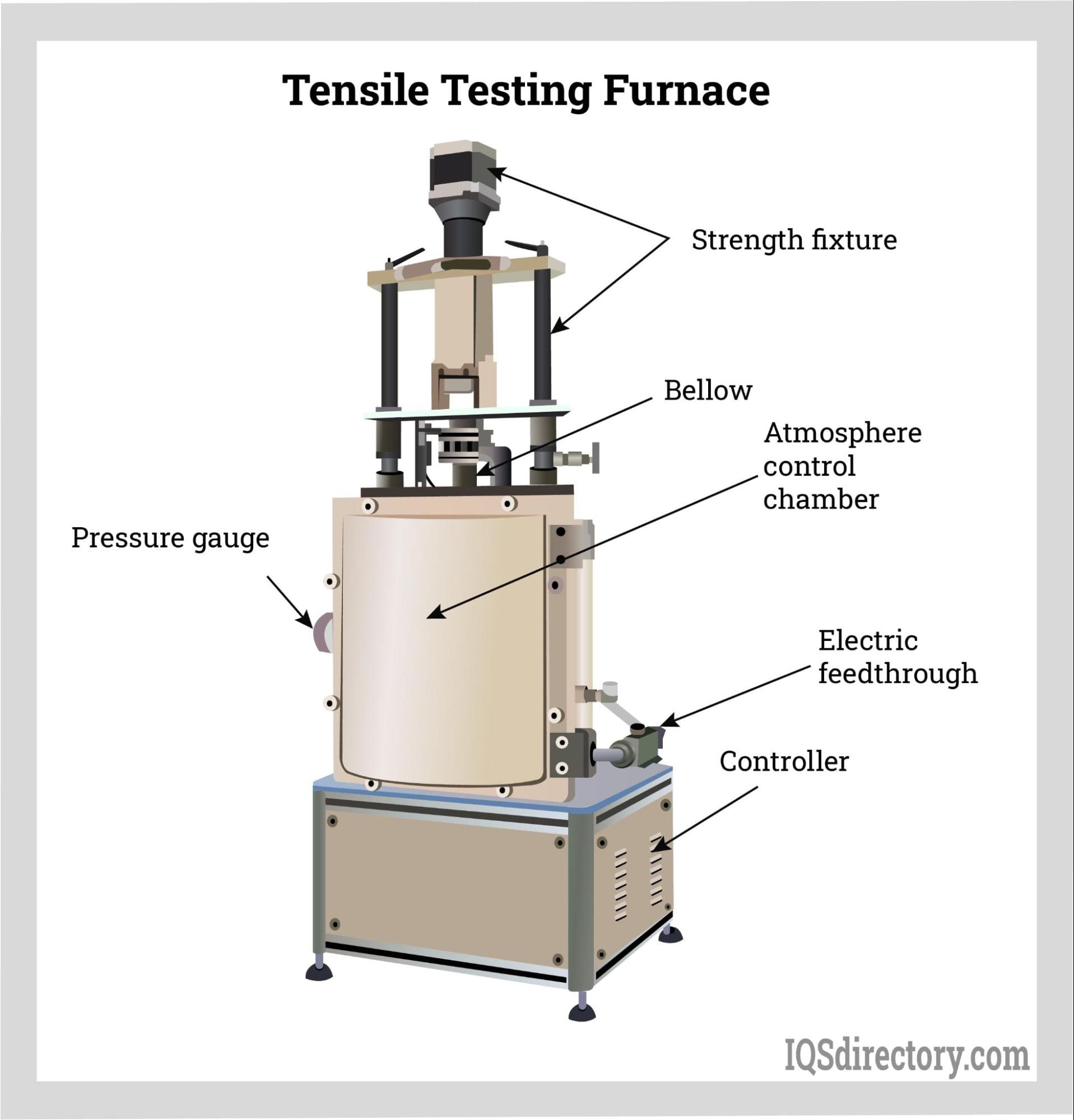

Tensile Testing Furnace

Tensile testing is a process for testing materials by subjecting them to tension until they break or fail. The properties tested are strength, elongation, and area reduction. The process is a destructive method of testing products to determine their point of failure and durability. Tensile testing is one of the several tests applied to products. The majority of tensile testing furnaces are small and laboratory size.

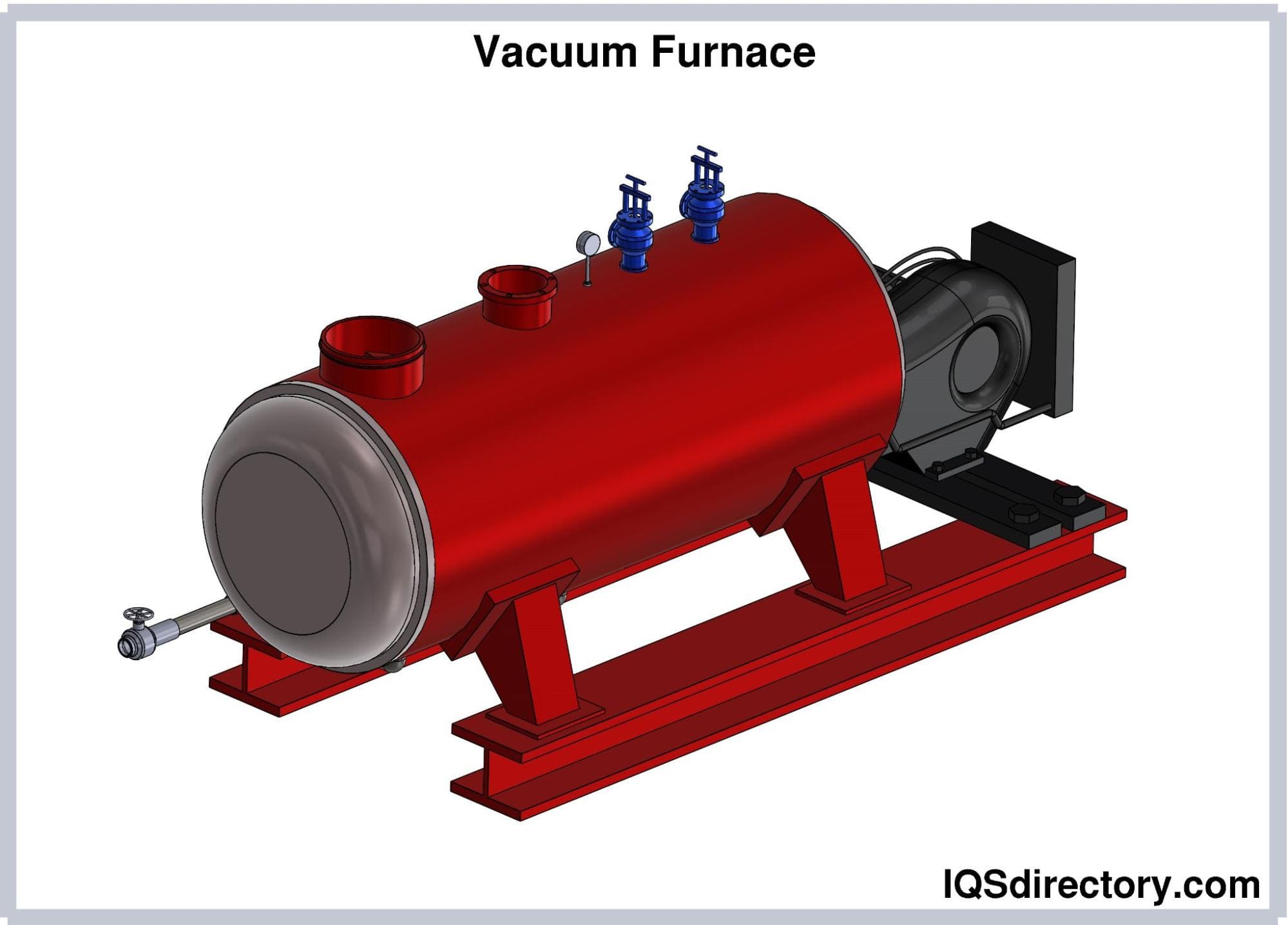

Vacuum Furnace

When a product is processed in a vacuum furnace, it is surrounded by a vacuum that prevents heat transfer through convection and removes contaminants. Normal heating of products to high temperatures causes oxidation. This is not present in a vacuum furnace since all oxygen has been removed.

Vacuum furnaces are an ideal method for quenching materials. They use an inert gas to quickly cool a treated piece. A vacuum furnace includes a vacuum unit, hydraulic system, and cooling system.

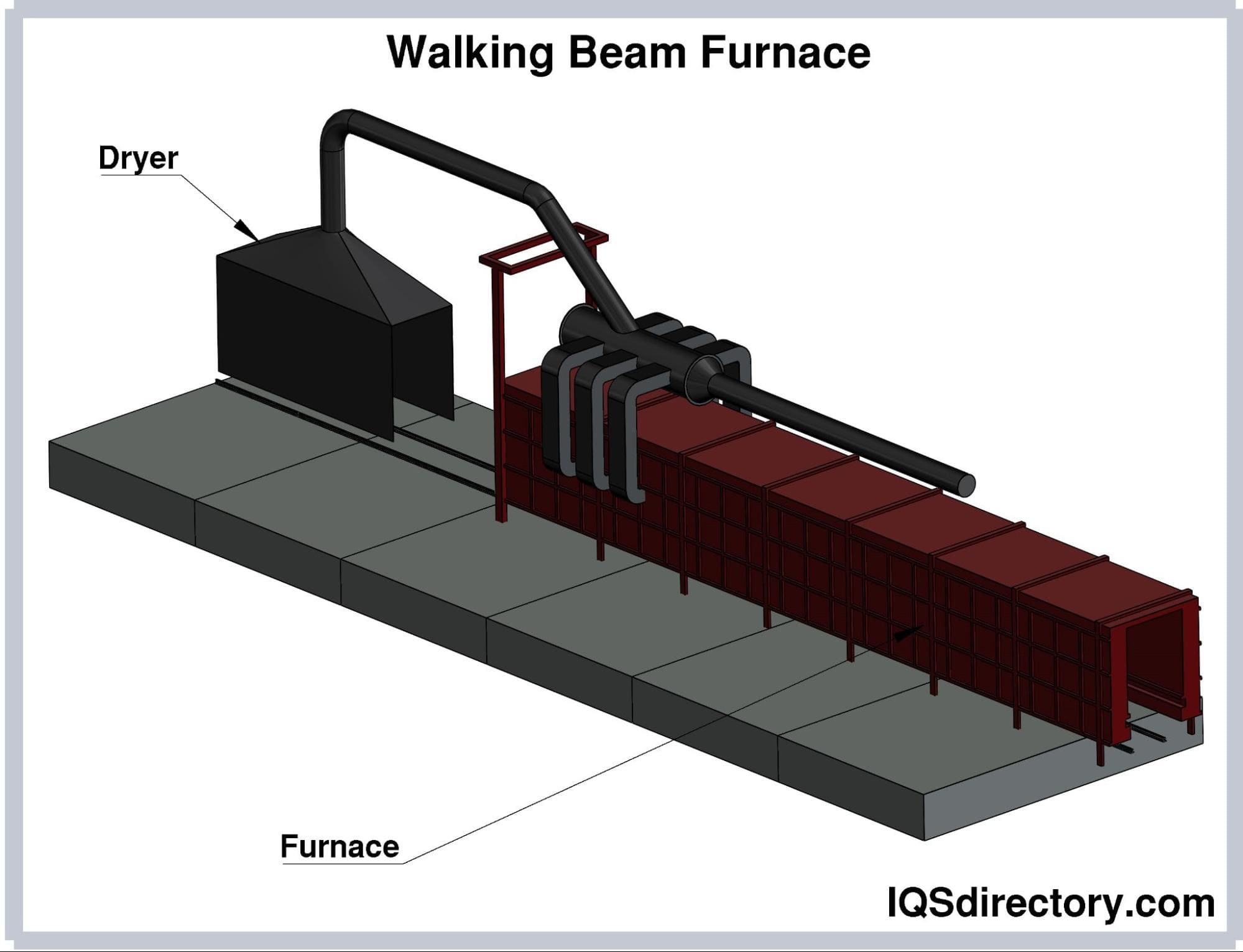

Walking Beam Furnace

Walking beam furnaces are efficient methods for processing large heavy parts. The main uses of walking beam furnaces are annealing, forging, heating, stress relieving, quenching, and tempering at a maximum temperature of 1100° C (2012° F). The material to be processed is gradually fed through the furnace by water cooled beams that lift and move materials in short steps.

The drive system of the furnace is protected from scales by sealing materials and an arrester. The cooling of the beams is to ensure a long life of usefulness. The door to the furnace opens as the beam enters and closes automatically.

Chapter Four – Methods for Heating Furnaces

Heat is generated in a furnace using a variety of methods, including the burning of a fuel or the conversion of electricity to heat. The most common type of furnace is fuel powered due to the expense of electricity. Though various forms of fuel are the most economical, there are processes where electricity has an advantage over fuels.

How a furnace is powered makes a difference in its design. Though uncommon, there are designs that still use solid fuels. A further classification of furnaces is where the heat process takes place, with electric furnaces using resistant or induction heating.

Heating Furnace Methods

Electric Powered Furnaces

Electric furnaces use a heating element to convert electricity to heat. A variety of materials are used to produce heating elements, with iron chrome aluminum and nickel chrome alloys being the most common. In the glass industry and research and development, precious metals are used as elements but are not used for industrial purposes due to their cost.

In some electric processes, various gases are added to the heating process of the furnace to improve efficiency and the distribution of heat.

Liquid Fueled Furnaces

The aspect of liquid fuels that is combustible is the fumes. The majority of liquid fuels are made from fossil fuels with other variations being hydrogen, ethanol, and biodiesel. Oil is the most common type of liquid fuel used to heat and reheat materials for treatments. The efficient operation of a liquid fueled furnace means complete combustion of the fuel without any residue.

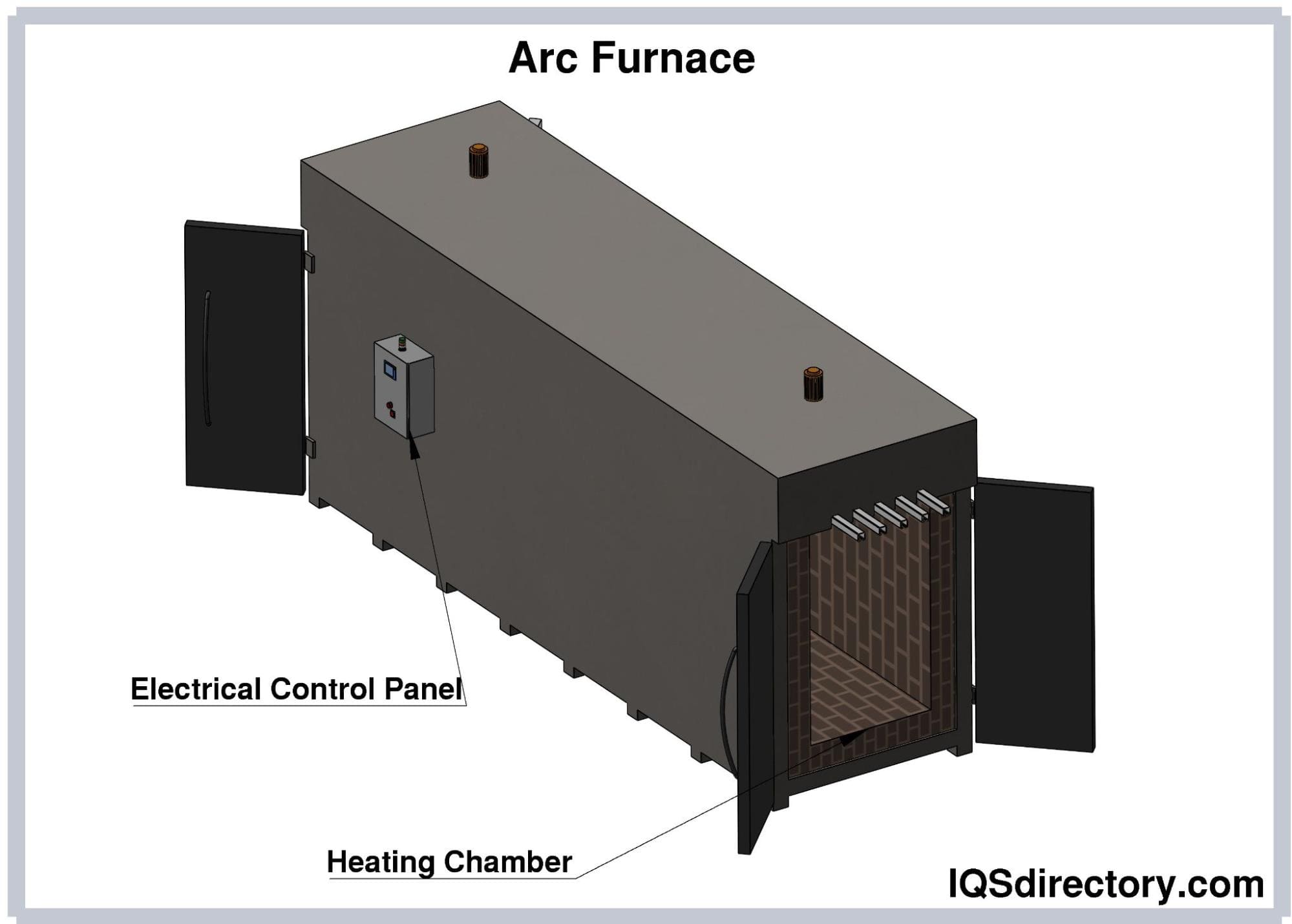

Electric Arc Furnaces

Electric arc furnaces are used to produce carbon steel and alloy steel by recycling ferrous scrap. Scrap is melted and converted to steel by high powered electric arcs that are formed by a cathode and one or more anodes. The scrap is loaded into a basket with limestone for slag formation then charged in the furnace. The energy required to melt the scrap and heat it is approximately 350 kWh to 370 kWh. The amount of energy necessary to power the arc varies depending on the mix of scrap and its composition.

Gas Powered Furnaces

Gas furnaces burn gas to produce heat for a variety of industrial processes. An enclosed space contains the gas until it reaches the temperature for the application. Gas furnaces have air, oxidized, inert, reducing, salt bath, or vacuum atmospheres. Natural gas is the main type of gas used for gas furnaces. For environmental protection, gas fired furnaces use oscillating combustion technology (OCT) to reduce nitrous oxide (NOx), a waste product from burning natural gas.

Chapter Five – Furnace Regulations

The major concern with industrial furnaces is their emissions, which are regulated by the Environmental Protection Agency (EPA). The federal New Source Performance Standards (NSPS) have stipulations regarding the size, function, and construction of industrial furnaces. The emissions of greatest concern are listed as Hazardous Air Pollutants (HAP).

Furnace operations are differentiated by furnaces designed for processing new products and those for heating. In 2011, the EPA published a list of pollutants and limits for each type. The publication was in compliance with part 60 of the Clean Air Act.

The International Organization for Standardization (ISO) has developed a set of specific regulations regarding industrial furnaces, which are found in ISO 13574, 13577, 13578, 13579, and 23459. They were first introduced in 2008 as ISO/TC 244 and have been progressively adjusted to include arc furnaces with ISO 13578: 2017.

- ISO 13574: 2017 – outlines the vocabulary associated with industrial furnaces

- ISO 13577 – has stipulations regarding safety standards for combustion and the handling of fuel, use of gases, and required protective systems

- ISO 13579 – outlines energy measurement and efficiency

- ISO 23495 – was enacted in 2021 regarding the requirements for converters and similar equipment

The American National Standards Institute (ANSI) has standards and codes regarding the safety, reliability, quality, and performance of industrial heating equipment.

The American Society of Mechanical Engineers (ASME) inspects and approves of industrial furnaces that are in compliance with their standards. The main concerns of the organization are safety and quality.

The United States Department of Energy (DOE) has established energy efficiency standards regarding industrial manufacturing equipment.

Conclusion

- An industrial furnace is a direct fired device used to provide heat for industrial processes that require heat in excess of 400° C (752° F).

- Through the combustion of fuels and gases, raw materials and products are heated by direct or indirect contact.

- The wide selection of industrial furnaces have different methods of performing their functions and use different fuels.

- Regardless of the differences in operation, all furnaces serve the primary purpose of providing heat.

- Industrial uses of furnaces tend to center around the annealing, melting, tempering, and carburizing of metals.

Source: https://www.iqsdirectory.com/articles/furnace.html

0 Response to "Natural Gas Fire Quench Furnace Radiation Continuous Natural Gas Fire Quench Furnace"

Post a Comment